1. Industry application:

1. Welding

1) Welding of carbide tools. Such as turning tools, milling cutters, reamer.

2) Welding of diamond bits. Such as diamond saw blades, abrasive tools, sawtooth welding. Welding of drill bits for prospecting, such as welding of a sub-drill and a claw bit.

3) Composite welding of metal materials such as brass, copper, stainless steel, etc.

2. Heat fitting and heat fusion equipment

1) The heating of the motor rotor and the water pump shell, and the heating of the bearing sleeve. Thermal fusion of plastic handle of tableware, etc.

2) Heating lamination of aluminum-plastic pipes, cables and wires; aluminum foil sealing used in food, beverage, and pharmaceutical industries, preheating expansion of metals, etc.

3. Quenching

Surface, inner hole, partial or overall quenching of various hardware tools, electric, hydraulic, pneumatic components, auto parts, motorcycle parts and other mechanical metal parts

4. Annealing equipment

It can perform overall or partial annealing treatment for various mechanical parts, and tensile annealing for stainless steel products within a diameter of 50

1) Heat the metal material for stretching, molding, embossing, etc. Such as steel pipe stretching, pipe bending, head smashing; iron wire, steel wire heating nailing

3) Heating and annealing metal materials. Such as steel pipe drawing, pipe bending; smashing head, iron wire, steel wire heating nails, stainless steel products

5. Smelting

1) Melting gold/copper/silver: 1-5kg

2) molten steel/aluminum: 1-3kg

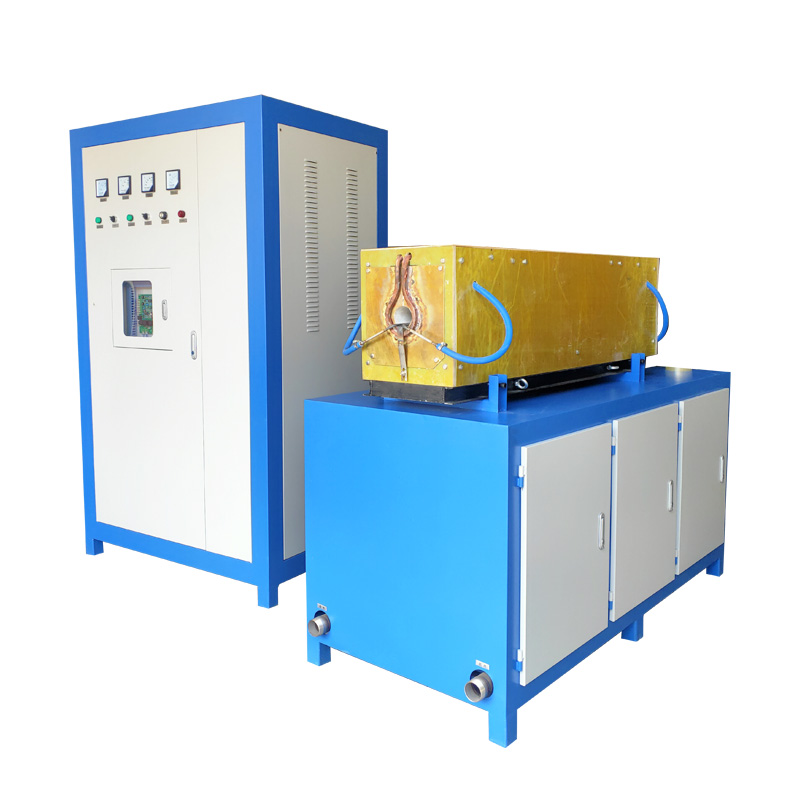

2. Main features:

1. Simple installation, only need to connect electricity and water to use, no need for special installation

2. Easy to operate: you can learn in a few minutes

3. Quick start: the heating can be started after the water is turned on

4. Less power consumption: Compared with old-fashioned high-frequency equipment, it saves power, and the smaller the workpiece, the less power consumption

5, the effect is good: the heating is very uniform, the temperature rises quickly, and the oxide layer is less.

6. Adjustable power: adjustable output power

7. Full protection: with overvoltage, overcurrent, overheating, water shortage and other alarm indications, and automatic control and protection

3. Operation steps

1. Water: Start the water pump and observe whether the water flow at the water outlet is normal.

2. Power on: first close the knife, then turn on the air switch at the back of the machine, and then turn on the power switch on the control board.

3. Setting: Select the operation mode (full automatic, semi-automatic, manual and foot control) according to your needs. When automatic and semi-automatic control, you need to set the heating time, holding time and cooling time (each time cannot be set to 0, otherwise it will not work properly). automatic cycle). Before using it for the first time and before you are proficient, you should use manual or foot control.

4. Start: Before each start, the heating power potentiometer should be adjusted to the minimum as much as possible, and then slowly adjust the temperature to the required power after starting. Press the start button to start the machine, at this time the heating indicator on the panel is on, and there will be a sound of normal work and the simultaneous flashing of the work light.

5. Observation and temperature measurement: During the heating process, visual inspection is mainly used to determine when to stop heating based on experience. Inexperienced operators can use a thermostat to detect the temperature of the workpiece.

6. Stop: When the temperature reaches the requirement, press the stop button to stop heating. You can start it again after replacing the workpiece.

7. Shutdown: The machine can work continuously for 24 hours. The power switch should be turned off when not in use, and the knife or the air switch at the rear of the machine should be turned off when not in use for a long time. When shutting down, the power should be cut off first and then the water should be cut off, so as to facilitate the heat dissipation inside the machine and the heat of the induction coil. Note: The machine should not work without load as much as possible, let alone run without load for a long time, otherwise, it will affect the performance and stability of the machine!

4. Precautions for use

1. In order to prevent electric shock, please ensure that the electrical specifications of the casing are reliably grounded.

2. The removal and installation of the sensor must be carried out after the heating stops.

3. Strictly implement the principle of water first and then electricity. Water shortage is strictly prohibited during the working process. The water quality and pressure of the cooling water inside the equipment and the sensor must meet the requirements of Table 2. In order to avoid blocking the cooling pipeline, if the water supply is supplied by a water pump, please install a filter at the water inlet of the water pump. The cooling water temperature should not be higher than 45°C, and the water flow rate should be 10T/h (softened water is recommended)

4. The equipment should be protected from sunlight, rain, moisture, dust, etc. When repairing or maintaining the equipment is required, it must be done one hour after the power is turned off.

5. In-machine cleaning method Blown with compressed air or blower every week. The circuit board is cleaned with a brush and then blown clean.

6. Ordinary users should clean the waterway of the machine with a special descaling agent (available from our company) every 4 months. When the machine frequently alarms the water temperature, or observes that the water flow of the water outlet decreases significantly, it should be cleaned immediately.

7. The sensor should be kept clean to prevent short circuit between turns.

8. This device cannot use single-turn inductors. Otherwise, the device may be damaged due to too small inductive reactance. In special cases, please consult the manufacturer.

9. When replacing the sensor, the contact surface between the sensor connection board and the transformer should be cleaned with sandpaper to maintain good electrical conductivity.

5. Technical parameters

model | RAG-15KW |

| model | RAG-25KW |

power | 15KW |

| power | 25KW |

Input Current | 23A |

| Input Current | 32A |

Oscillation frequency | 30-100KHZ |

| Oscillation frequency | 30-100KHZ |

Input voltage | Simplex220V |

| Input voltage | 三相380V |

molten gold | 1-3kg |

| molten gold | 1-5kg |

volume(cm) | 42*20*36 |

| volume(cm) | 57*22*46 |

weight(KG) | 20 |

| weight(KG) | 28 |

6. Troubleshooting and troubleshooting

Fault | possible reason | Solution |

After turning on the power switch, the "Power" indicator does not light up |

1 The panel power switch is in poor contact 21P air circuit breaker trip 3 Phase loss

|

1 Close and open, repeat several times 21P air open to send on 3 Check the power supply voltage

|

After stepping on the foot switch, the work light does not light up |

1 Foot switch lead off 2 The AC contactor is not closed or the contact is poor 3 Poor contact of the sensor

| 1 Check the foot switch lead wire or AC contactor or sensor |

Adjust the panel power to the maximum, no current indication or the current is too small |

1 The number of turns of the inductor is too much or the load is too heavy 2 sensor short circuit 3 Poor contact at the sensor 4 half bridge work

|

1 Reconfigure the sensor 2 reboot after separation and it works fine 3 Grinding or pickling at joints 4 Contact the manufacturer

|

The workpiece cannot be heated after being placed |

1 The external power supply capacity is small or the wire is too thin 2 phase loss 3 The number of turns of the inductor is too much or the load is too heavy 4 half bridge work |

1 Increase the power capacity 2 Check the three-phase power supply 3 Reconfigure the sensor 4 Contact the manufacturer

|

Overcurrent alarm |

1 The contact of the sensor is bad or short circuit 2 The contacts of the AC contactor are in poor contact 3 Too many or too few turns of the inductor 4 ignition at the external power connector 5 Poor contact of high-frequency cables 6 Power board failure 7 There is a spark inside 8 The resonant transformer is bad |

1 Check the sensor, high frequency cable, external power supply 2 Replace the AC contactor 3 Reduce the number of inductor turns 4 Check the power tube

|

water pressure alarm |

1 The water pressure is too low 2 limescale clogging 3 The water pressure switch is broken |

1 Increase the water pressure 2 Clean the limescale 3 Replace the water pressure switch |

water temperature alarm |

1 The water temperature is too high 2 The water flow is too small 3 water pipe blockage 4 Too much scale inside |

1 Change the cooling water 2 Increase the water pump or water pressure 3 Clean with descaling agent 1 40 4 Replace the water temperature relay |

浙公網安備 33038102331513號

浙公網安備 33038102331513號